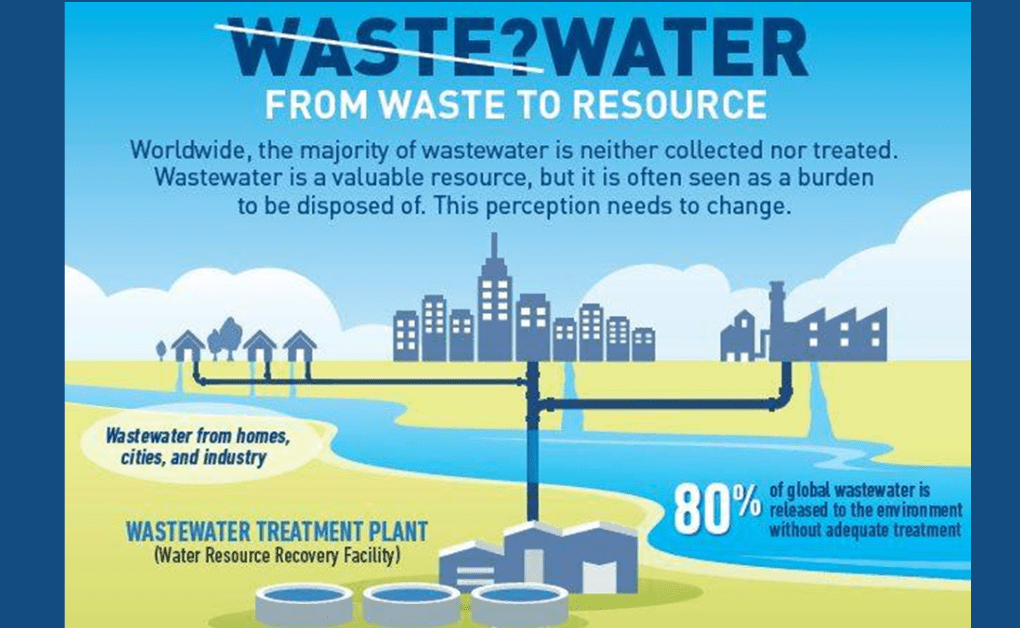

India is facing a water crisis, and by 2030, the demand for water is expected to be twice the supply. With this concerning situation, one has to wonder how to establish strong water infrastructure in India. Many are unaware that wastewater can be effectively converted into reusable water. While water is a renewable resource, it takes a long time for nature to remove toxins through evaporation and rain. Fortunately, modern wastewater treatment technologies can expedite this process, providing safe and reusable water.

Governments around the world are taking various steps and investing in projects to conserve water. One such promising initiative in India is the Ethanol Blended Petrol Programme (EBP Programme). Ethanol, produced from the fermentation of sugars, can be combined with petrol after proper treatment. It can reduce the consumption of petroleum fuels and air pollution, offering cost savings and environmental benefits.

WHAT IS AN EFFLUENT TREATMENT PLANT (ETP)

Industries such as pharmaceuticals, chemicals, automobiles, textiles, food processing, electrical and electronics, hospitality, and more rely on water for their operations. However, the resulting chemical, physical, organic, and biological materials, known as effluents, pollute the water, making it unsuitable for direct discharge into the environment. Effluent Treatment Plants (ETPs) are designed to remove these pollutants from industrial wastewater, making it suitable for safe discharge or reuse. ETPs are also utilized in Zero Liquid Discharge (ZLD) plants to further reduce the need for fresh water, thus preserving the natural environment.

WASTEWATER DISINFECTION

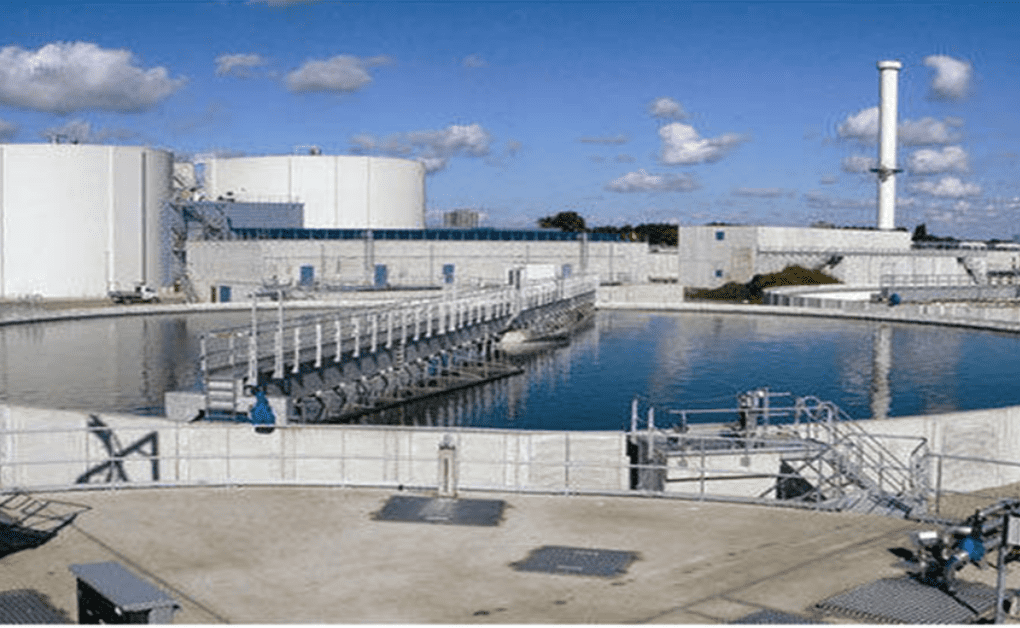

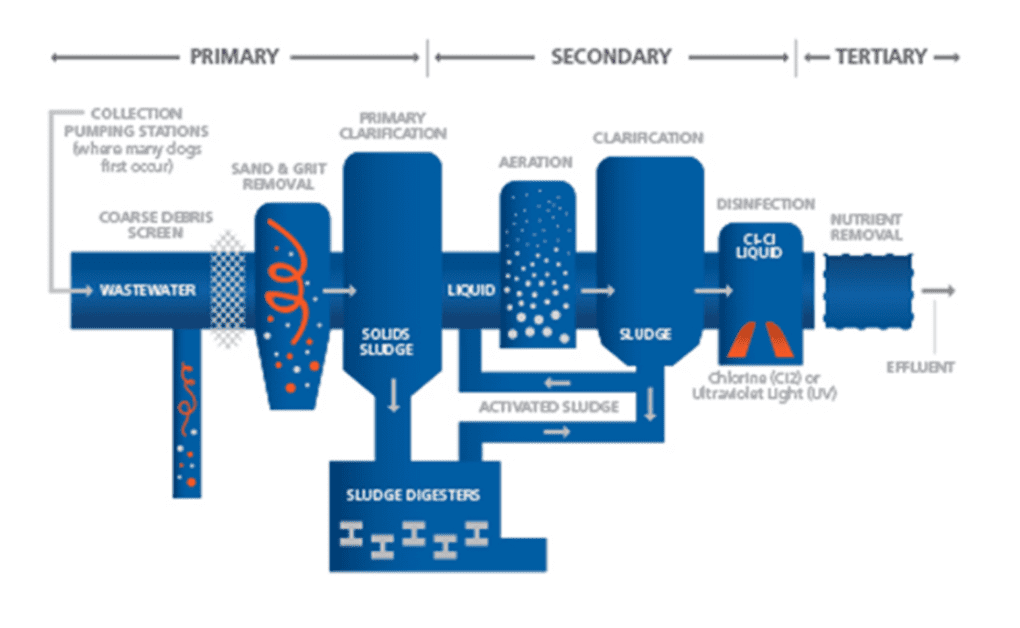

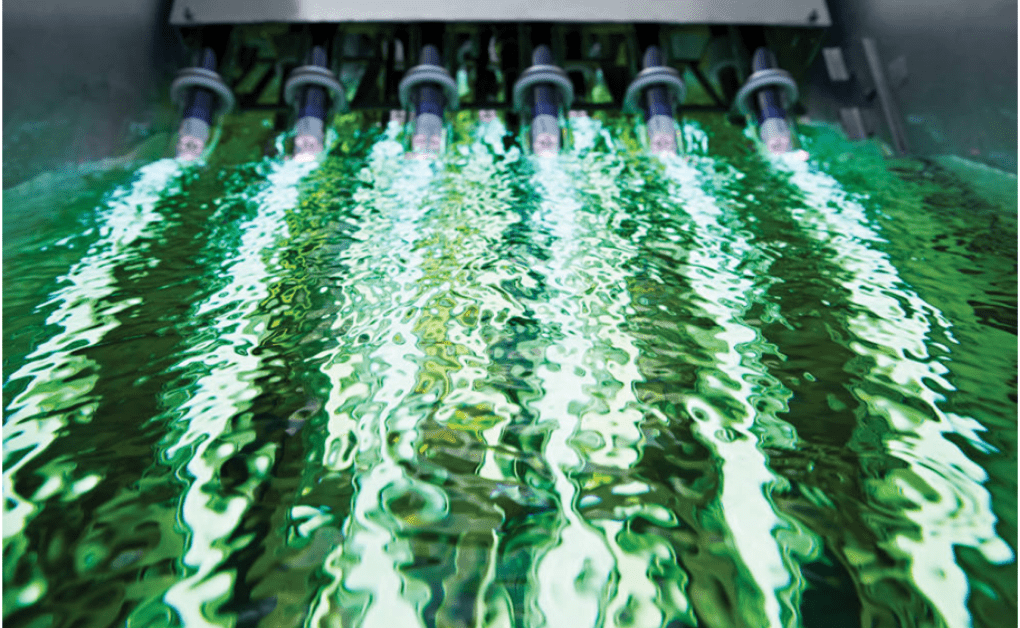

After primary, secondary, and sometimes tertiary wastewater treatment, the final step is wastewater disinfection. This process aims to remove biological contaminants from the treated water to prevent the spread of waterborne diseases. Wastewater disinfection is vital as it eliminates high levels of microbial contamination before releasing it into the environment. Technologies such as ultraviolet irradiation (UV) and chlorine are commonly used for disinfecting wastewater. Although chlorine is widely used, it has drawbacks such as insufficient protection against certain microorganisms, corrosion of infrastructure, and alteration of water pH, making it unsuitable for reuse applications such as irrigation.

To address these issues, governments are promoting the use of alternative disinfection methods like UV (ultraviolet disinfection). UV is a powerful disinfectant that does not produce harmful byproducts and is non-toxic. The knowledge and use of UV disinfection have grown significantly in the last two decades, and it has been proven effective against various pathogens, including those resistant to chlorine.

Image credit: Environmental Science & Engineering Magazine

UV disinfection of wastewater is safe, non-toxic, and can be monitored in real-time using UV intensity sensors and monitors. However, the presence of certain substances in wastewater can affect the performance of UV disinfection systems.

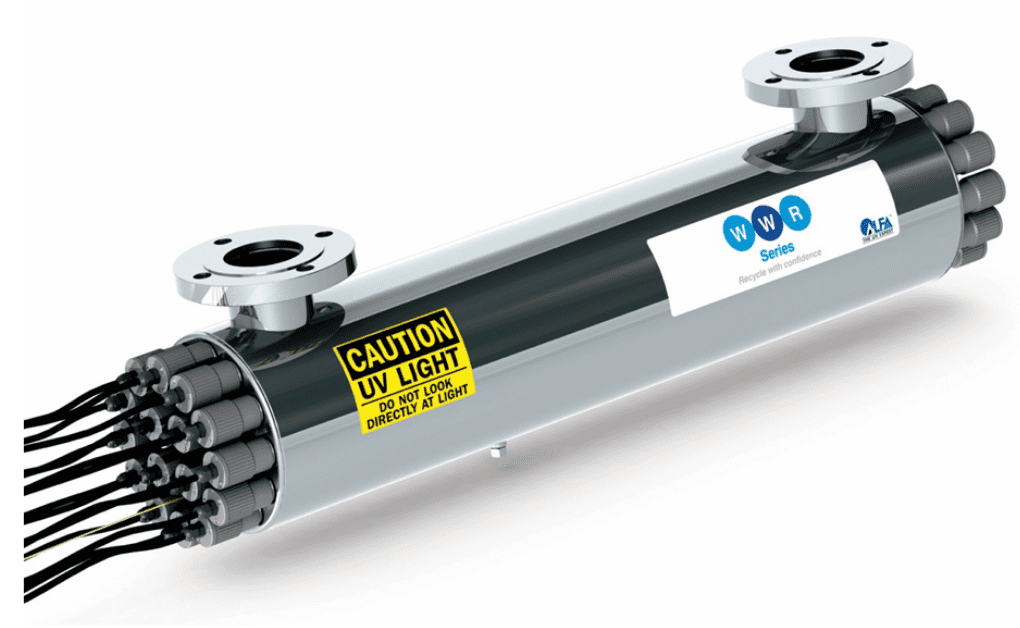

Alfaa UV Wastewater Treatment Solutions

Alfaa UV offers wastewater disinfection solutions for municipal, industrial, and recreational water applications. The company is an ISO 9001:2000 certified leader in its field, providing high-standard water disinfection for various industrial applications.

Why Use Alfaa UV Systems for Wastewater Disinfection or for Industrial Wastewater Treatment?

UV technology for water disinfection is being widely used due to its affordability and environmental benefits. Alfaa uses environmentally friendly UV technology for wastewater disinfection, addressing the global issue of uncontrolled release of chlorinated compounds into the environment.

-

GoGreen with Alfaa

By opting for UV wastewater disinfection instead of chlorination, Alfaa contributes to environmental conservation.

-

Chlorine Disinfection By-Products

Alfaa’s UV wastewater disinfection process eliminates the production of harmful chlorine byproducts, safeguarding the environment and human health.